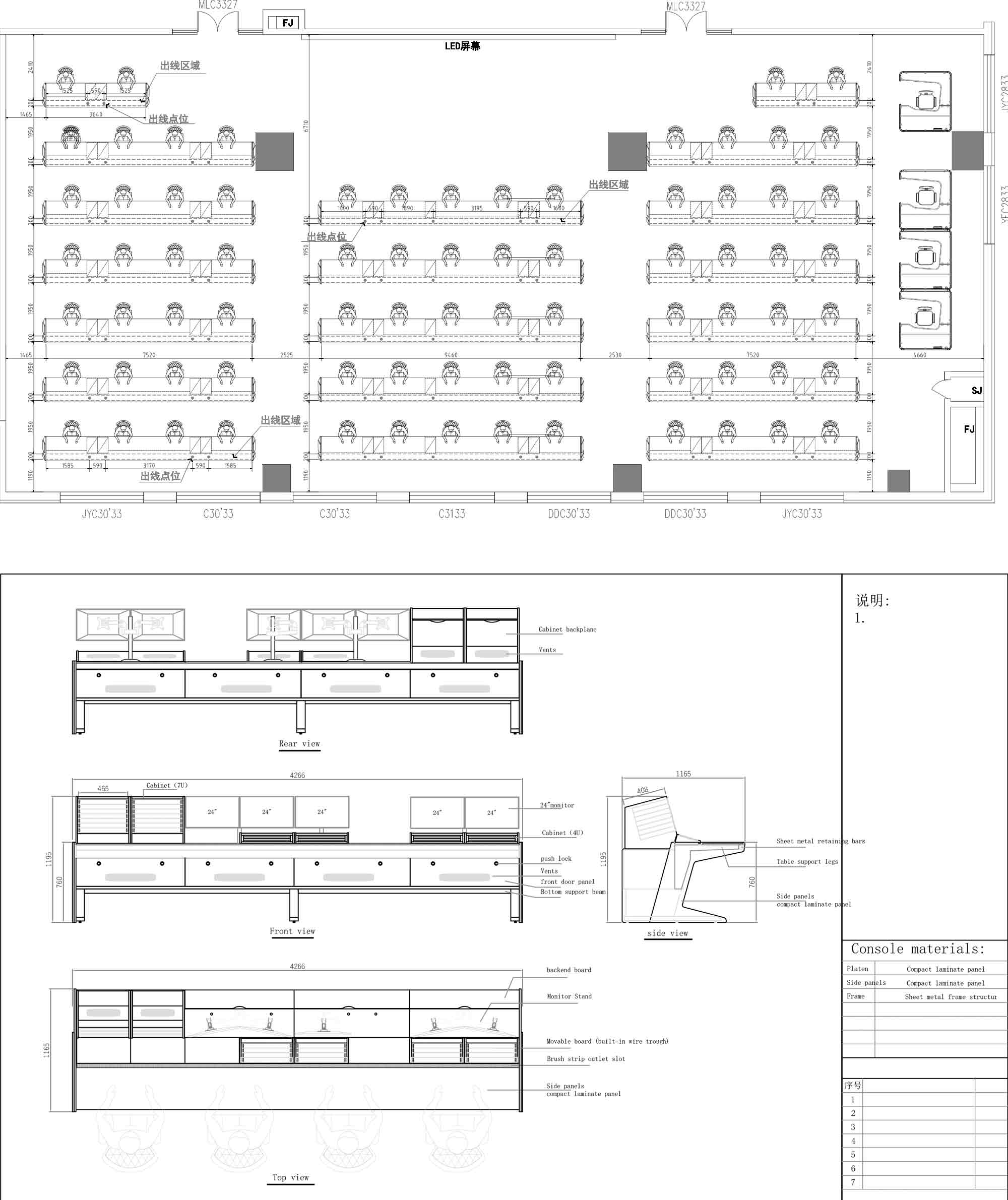

Room & Technical Drawings

At UDWEN console, we understand that ergonomic considerations are key to creating successful control rooms and mission-critical environments. Our design team collaborates closely with clients to study and create plans for rooms where technical furniture will be installed. We adhere to the UNE-EN 11064 standard, which regulates ergonomic design parameters for control centers. Our team provides detailed designs for technical furniture, whether standard, modified, or custom-made. Additionally, we optimize the layout to enhance efficiency in operator interactions, movements, and repetitive tasks.

Rendering

UDWEN uses cutting-edge 3D technology to create realistic renderings of products and environments. Our specialized team produces virtual images of projects from various angles, showing finishes, layouts, and lighting. These renderings help in decision-making by allowing clients to identify errors or improvements before production. We ensure that the project meets the initial requirements, paying close attention to every detail.

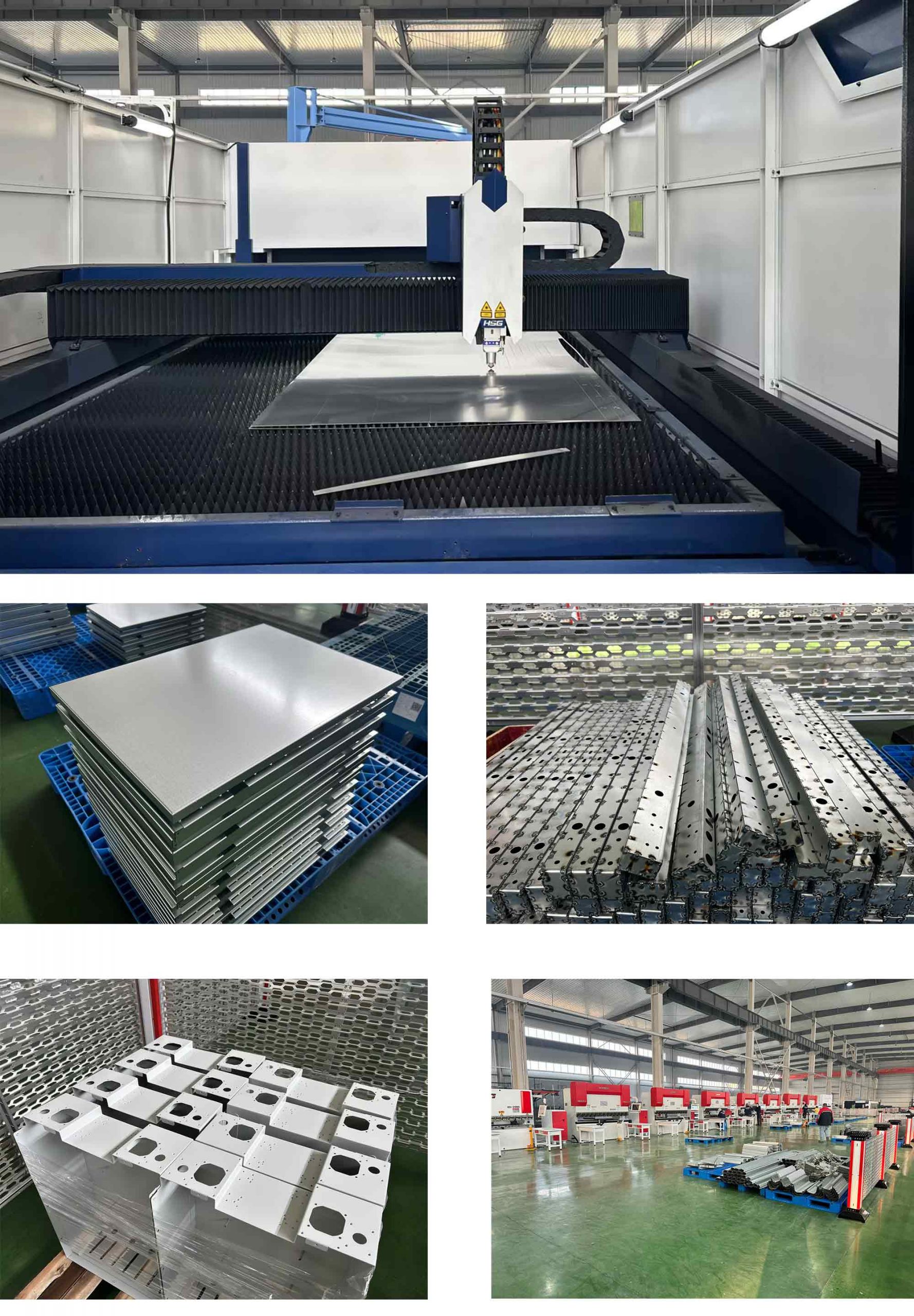

Manufacture, Assembly & Packaging

UDWEN console products are manufactured in a state-of-the-art production center, operating under strict ISO 9001 quality standards. All products are pre-assembled in a 1,200 sqm assembly area, undergoing rigorous quality control before packaging and shipping. This process guarantees that products arrive in perfect condition for quick installation. We dedicate significant resources to product packaging, ensuring that items are well-protected during shipment. For large projects, we coordinate packaging with customers to organize partial shipments and on-site installations. Our assembly and logistics teams provide tailored services for each project.

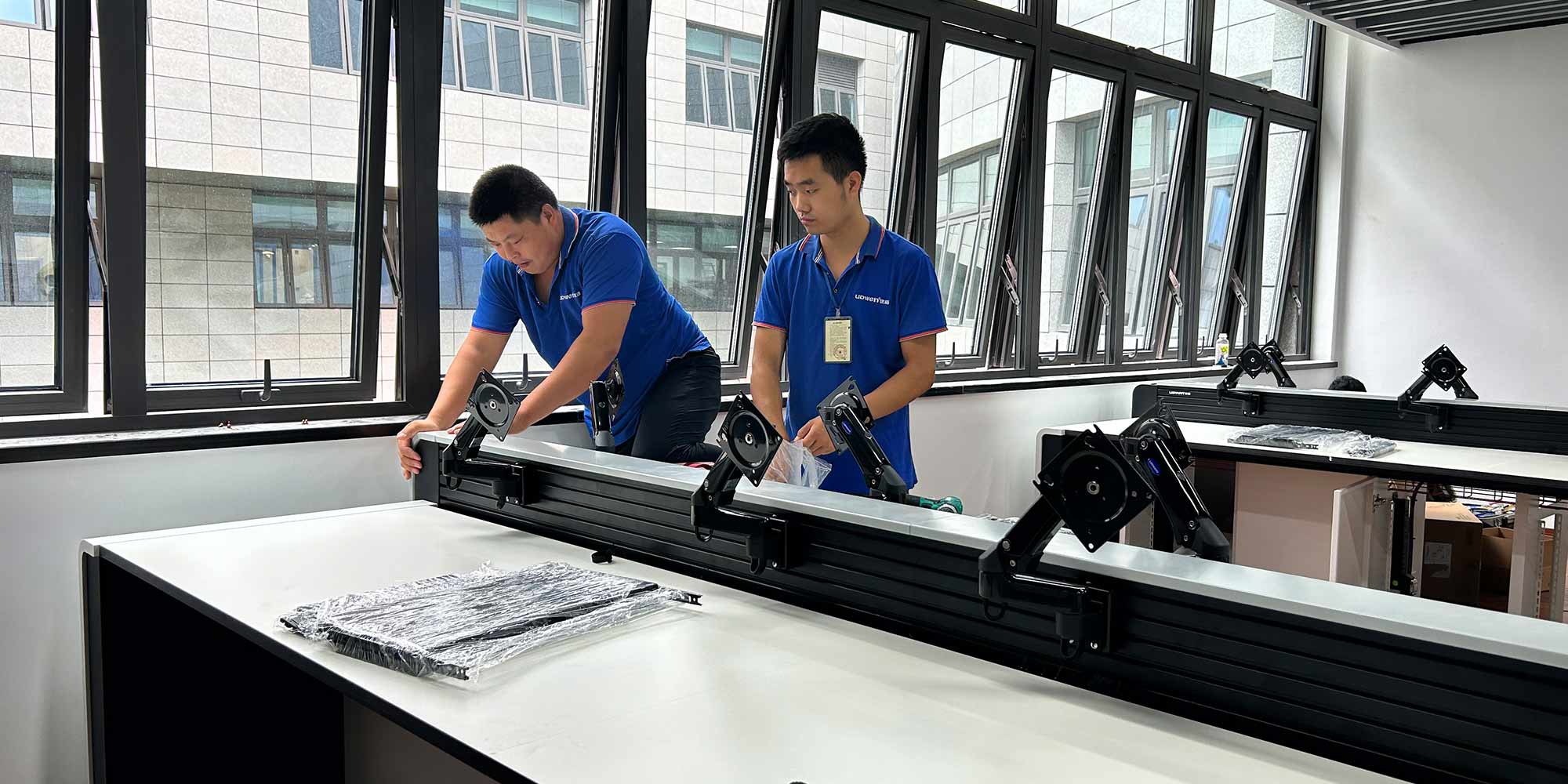

Shipments & Installation

UDWEN console ships products globally, and our assembly team ensures safe, high-quality installation. For each project, we create specific assembly instructions to enable efficient and error-free installation. Upon request, UDWEN can send an installation supervisor or assembly team to oversee the process on-site.